Three years ago, machine operators at Tai Sin Electric, a Singapore cable manufacturer, had to fill in a daily report of their work using pen and paper. All these data were then typed into a spreadsheet software.

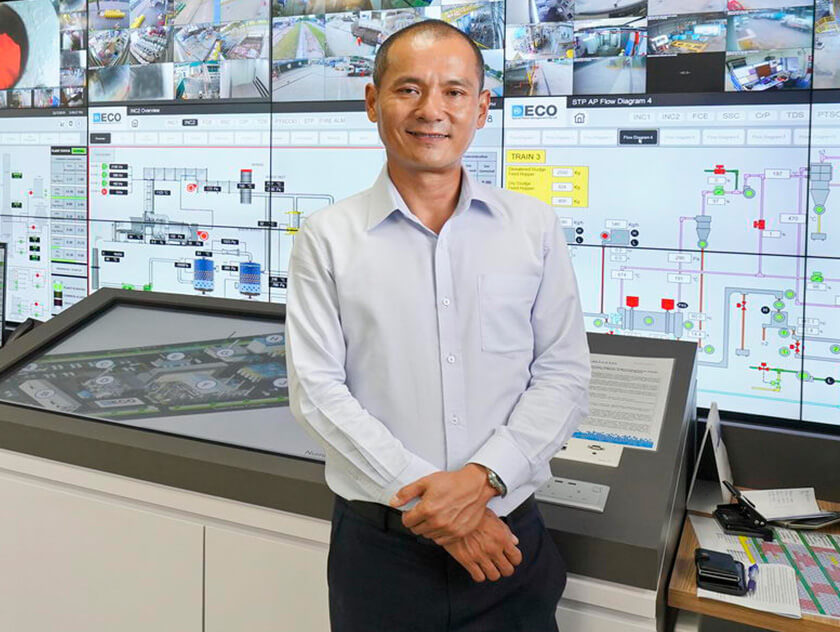

“This manual process was tedious and time-consuming, affecting our productivity. We also needed someone to check for errors,” says Mr Lin Chen Mou, Tai Sin’s Executive Vice President and General Manager.

Even with 40 years of experience producing wires and cables for infrastructure, industrial, commercial and residential projects, Tai Sin needed to find new ways to improve productivity. “If you don’t digitalise and increase efficiency, you will lose out to the competition,” he says.

Since 2016, the local SME has digitalised much of its manufacturing processes, with a digital dashboard to track all of its production activities.

Initially, the company started by adding sensors to its legacy machines to record data, so workers no longer need to fill in the reports manually. However, Tai Sin did not have the expertise to analyse the data and find ways to improve performance.

To resolve these issues, Tai Sin participated in the Economic Development Board’s Smart Industry Readiness Index (SIRI) assessment in 2018, on JTC’s advice. The assessment shed light on issues from improving connectivity across the shop floor to preparing workers for digitalisation.

After SIRI, Tai Sin joined the Workforce Singapore-McKinsey Industry 4.0 Transformation & Job Redesign Programme. Eight Tai Sin staff were reskilled so that they can help the company make sense of equipment data.

Other employees were sent for Industry 4.0 courses or even overseas learning journeys to visit leading companies. Some employees also attended English classes so that they can operate the new digital systems.

“Before this, some of our staff could only operate one type of equipment. Now, they are trained to use different machines,” Mr Lin says. This flexibility means Tai Sin no longer need to retrain staff if there are changes in orders since they can switch to operate different machines easily. To date, Tai Sin has upskilled a third of its employees.

McKinsey’s consultants also advised Tai Sin to integrate the data collected from different software systems and platforms into a single data warehouse for clearer visualisation through a single digital dashboard. This allows the company to track its processes in real-time, to spot irregularities or production issues at a glance.

For example, by analysing the dashboard data, Tai Sin’s management was able to discover anomalies when machines tend to stop running in between the changeover of day and night shifts. After investigation, they realised that staff would switch off the machines 30 minutes before their shift ends as they needed to prepare to catch a chartered bus, which leaves on the dot.

Workers in the next shift would have to turn on the machine when they arrive. To remove this downtime, Tai Sin asked the chartered bus to leave 15 minutes later instead, giving sufficient time for hand over between the two batches without the need to stop the machines.

This single change decreased material wastage from starting and stopping the machines by 30% each month, says Mr Lin.

Digitalisation also increased workforce productivity by 34%, in part because each worker’s performance can now be clearly measured. Staff who hit their targets will be rewarded with better bonuses.

Since digitalisation, Tai Sin has increased its monthly production capacity from 800 tonnes to over 1,000 tonnes of copper. It also saw its revenue grow by 27.5% since 2016.

The transformation gives Tai Sin’s clients more confidence in their ability to deliver quality products on time. “When some of our clients heard about the new dashboard, they wanted to find out more. We brought them on factory tours to share how the technology has improved production quality and procedures,” shares Mr Lin.

Looking forward, Tai Sin is looking to further digitalise its shop floor, with plans to introduce robotic arms to automate repetitive tasks.

“We are also planning to digitalise other aspects such as logistics,” Mr Lin shares.

These initiatives are essential to the company’s survival, he adds. “Investing in digitalisation is essential to help us keep up with the times, even if the benefits can’t be seen immediately.”