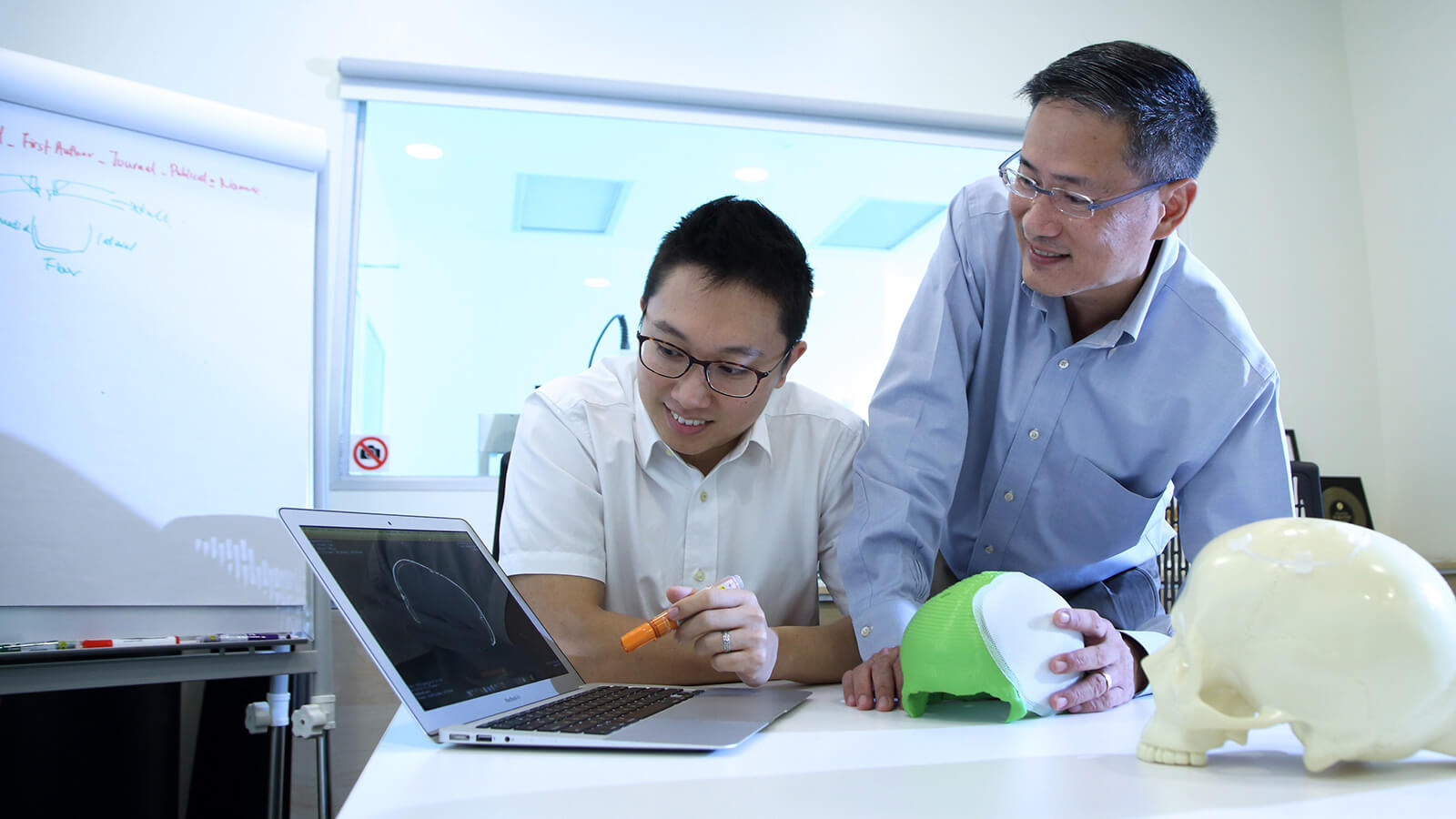

When Osteopore was looking for a new premise for its manufacturing facilities in 2015, it could not just move into any industrial space. The company designs and develops bioresorbable polymer implants for neurosurgical, orthopaedic and maxillofacial surgery use, and they supply them to hospitals in Singapore as well as Asia, America and Europe. It employs 3D printing technology to produce these synthetic tissue engineered products that function as a ‘scaffold’ to aid guide tissue regeneration with the patient’s own bone cells.

What this means is that Osteopore needs its facility to be located in a premise that is clean due to its products and production needs. “Mixed use industrial buildings are not ideal for medical device manufacturing. The neighbours may have production that produce high level of dust, vibration or by-products that could inadvertently affect the quality of our products,” says Goh Khoon Seng, 55, CEO of Osteopore.

So when Osteopore decided to move from their former premise at Science Park 2, JTC MedTech Hub @ MedTech Park was an ideal choice as it houses a cluster of medical devices companies that have similar requirements on their space like Osteopore. “From the stage when the material reaches our manufacturing space in MedTech Hub, it needs to be in as clean an environment as possible. This provides confidence that our products can be effectively sterilised. Seeing the clean environment that we are in also provides additional assurance to our partners and regulatory auditors on the quality of our processes and products,” says Mr Goh.

Another benefit of being at MedTech Hub is that it is near National University of Singapore and Nanyang Technological University (NTU), two organisations they work closely with. “We work with NTU Centre for Bone Tissue Engineering who are developing 3D printing for medical devices,” Mr Goh says. “NTU is only 10 minutes away from us.”

The networks at MedTech Hub provide us with collaboration opportunities with similar companies to enjoy economies of scale. This helps to keep our costs low and makes our business more sustainable.

Since its move into MedTech Hub in March 2015, the company has established networks with other medical companies there. For example, they have been sharing a service provider with Contract Sterilisation Services (CSS) who also have a clean room. Like Osteopore, CSS needs a service provider to collect, wash and deliver clean gowns. “CSS and us share the same service provider to wash our clean room gowns. This improves the efficiency for the service provider,” Mr Goh says. In addition, Osteopore taps on the shared facilities at MedTech Hub. “The conference room is reasonably priced and convenient. There is no need for us to have a huge meeting room within our space. I hope to be able to use it for product training for our sales team and doctors in the future.”

Mr Goh also sees more opportunities for collaborations with other companies at MedTech Hub, for example with AQS Labs Pte Limited, which provides quality training. “The potential for us hiring them to train our staff is high,” Mr Goh says.

“The networks at MedTech Hub provide us with collaboration opportunities with similar companies to enjoy economies of scale. This helps to keep our costs low and makes our business more sustainable,” concludes Mr Goh.